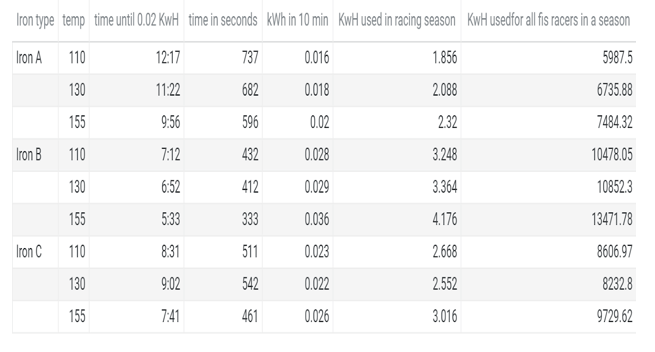

Energy consumed by waxing irons of all FIS Racers

Electricity is an essential part of modern life and important to the U.S. economy. People use electricity for lighting, heating, cooling, and refrigeration and for operating appliances, computers, electronics, machinery, and public transportation systems. The environmental problems directly related to energy production and consumption include air pollution, climate change, water pollution, thermal pollution, and solid waste disposal. In an attempt to show the concern of energy use in my daily life, I performed an experiment. Which of these ski wax irons is most efficient at three different temperatures?

Procedure

I started by gathering together the necessary material for this experiment such as an electricity usage monitor, three different types of irons, and a reliable outlet. Then I plugged in the electricity usage monitor into the outlet and plugged the first Iron A into that. Once I plugged it in I kept a stopwatch ready to record the times. I set the iron to the desired 130 C temperature to start off. I carefully watched the monitor until it reached .02 Kilowatt hours where I would then stop the stopwatch and record the time on my phone. I continued this procedure with the three irons and three different temperatures(110,130,155 C), which totaled to 9 tests. Iron A was a high quality from the brand swix, Iron B was an economy grade racewax brand iron, and iron C was a lower quality swix iron. Once I gathered all my results, I created a table and manipulated my numbers to calculate efficiency. I made some assumptions about the amount of days in a ski race season(calculating off-days and holidays) and the average amount of time it takes to wax a ski because no data could be found regarding that criteria.

Conclusion

Iron A was significantly more efficient than the other two irons. My thinking behind this is that since it's a higher quality iron, it can hold a more accurate and consistent temperature and uses less energy to maintain the temperature once it gets there. Per year the average Kwh usage for a single iron is 2.8 kWh. This might not seem like a lot but if the amount of fis racers is factored in thousands of KwH of electricity are being consumed. A household iron uses 52 Kwh of iron per year which means they are about 25 times less efficient than a ski wax iron. In Vermont, it cost 18¢ / kWh. This means one ski academy could save that much money if they did not use irons at all and used a rub on technique for ski wax. It is best to use a more energy efficient ski wax iron model to conserve as much energy as possible.

Observations-(temp in C)